https://news.usni.org/2018/07/11/se...-new-engine-turbine-blades-damaged-sea-trials

Second Zumwalt Destroyer Needs New Engine After Turbine Blades Damaged in Sea Trials

By: Megan Eckstein

July 11, 2018 10:56 AM • Updated: July 11, 2018 6:05 PM

Destroyer Michael Monsoor (DDG-1001) underway during trials. BIW Photo

This post has been updated to include a statement from Rolls-Royce, and again to include a statement from Naval Sea Systems Command.

Zumwalt-class destroyer Michael Monsoor (DDG-1001) will need to have a main turbine engine replaced before the ship can sail to San Diego for its combat system activation, after suffering damage to the turbine blades during acceptance trials, the Program Executive Officer for Ships told USNI News.

Rear Adm. William Galinis said today that Monsoor remained in Bath, Maine, for a post-delivery availability and that, “regrettably, coming off her acceptance trials we found a problem with one of the main turbine engines that drives one of the main generators; we’re having to change it out. So we’re working very closely with Bath Iron Works, with Rolls-Royce to get that engine changed out before she leaves Bath later this fall and sails to San Diego to start her combat system activation availability next year.”

After his remarks at a Navy League breakfast event, Galinis told USNI News that the MT30 marine gas turbine showed no signs of malfunctioning during the sea trials, but the damage was found in a post-trials inspection.

“The problem we had coming off of acceptance trials was actually the turbine blades – so think of a jet engine on the side of an airplane, the blades that you see – we actually had some dings, some damage to those turbine blades,” he said.

“We found that after the sea trial through what we call a borescope inspection, where we actually put a visual and optical device inside the turbine to kind of look at this. And we determined that it was best to change that turbine out before we actually transited the ship to San Diego.”

Monsoor completed acceptance trials in February, and the Navy accepted partial delivery of the ship in April. According to Naval Sea Systems Command (NAVSEA), the damage was discovered in February during a post-cleaning inspection of the engine.

Galinis said part of the reason it has taken so long to replace the engine is that, with the MT30 being so large, a special rail system is needed to remove the engine and put in a new one. That system hadn’t yet been designed when the Navy realized it needed one, so engineers had to finish the design and then install the system.

“So that’s what’s taken us a little bit,” the rear admiral said.

Galinis said the Navy has already checked USS Zumwalt (DDG-1000) and found no damage to its main turbine engine.

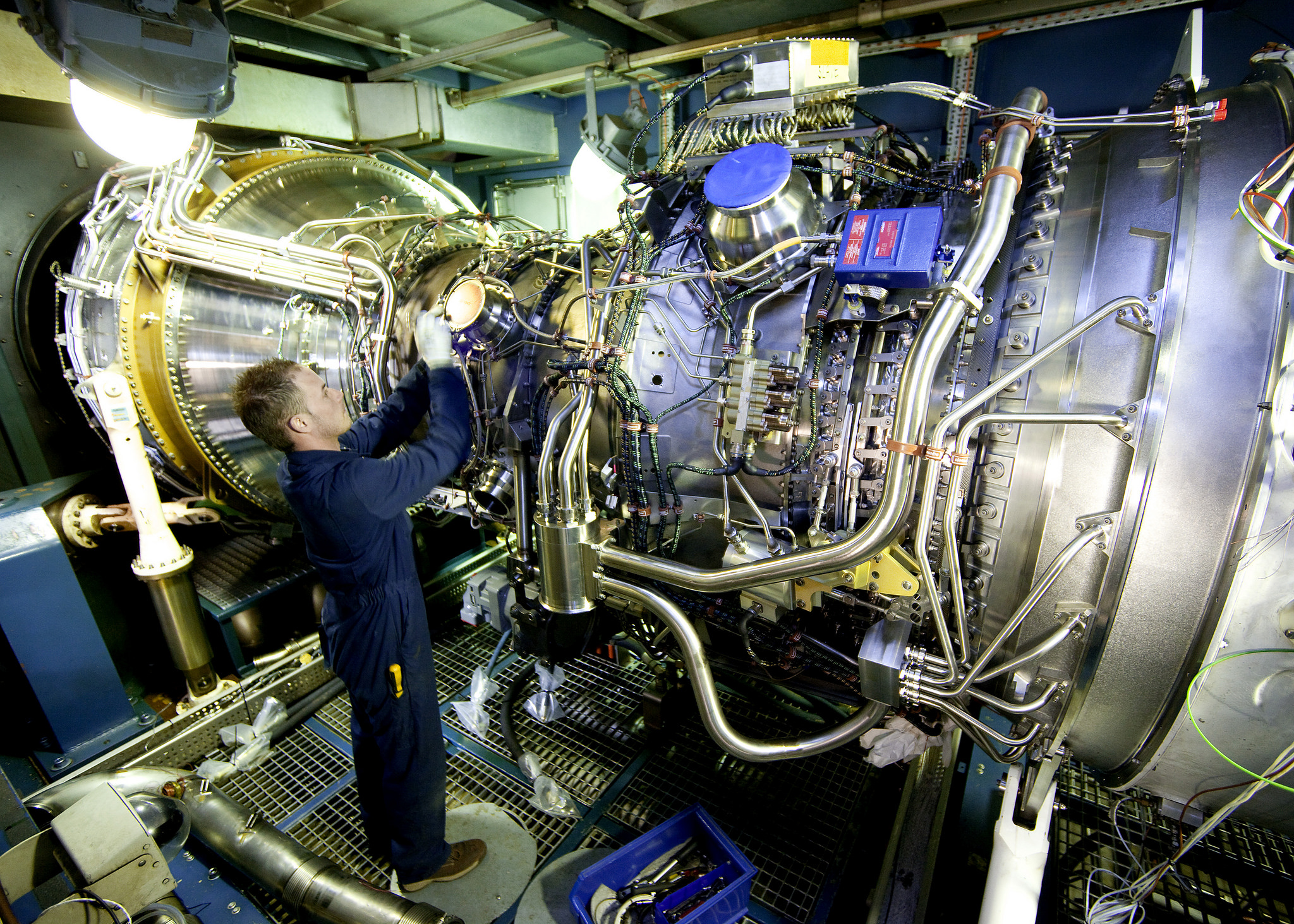

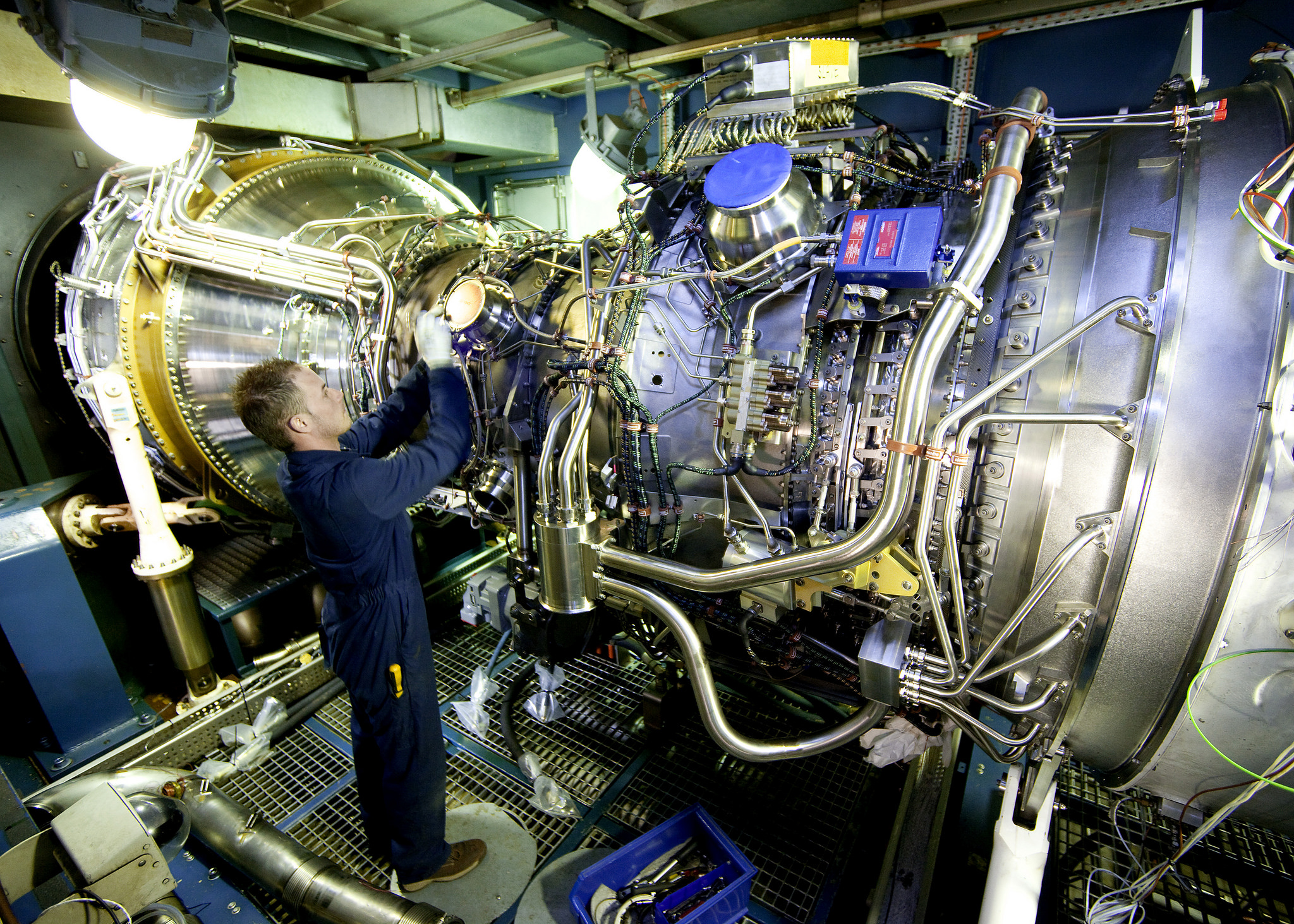

An MT30 in 2010. Rolls-Royce Photo

In the U.S., the $20-million Rolls-Royce MT30 is installed on not only the Zumwalt-class but also on the Navy’s Freedom-variant of Littoral Combat Ships. Internationally, the gas turbine –derived from Rolls’ Trent 800 aviation engine – is in use on the U.K. Royal Navy’s Queen Elizabeth-class carriers, the under-construction Royal Navy Type 26 frigate, the planned Daegu-class frigate for South Korea and the Italian Navy’s new Trieste amphibious warship.

The engine, introduced in 2001, can generate up to 40 megawatts of power and is the key to the Zumwalt-class’s Integrated Power System. The MT30s drive the destroyer’s massive electrical grid that drives everything from the ship’s sensors to a massive electric motor that drives the ship’s shafts.

“We’re working closely with the U.S. Navy and the team at Bath Iron Works to swap one of the two MT30 gas turbines on Michael Monsoor,” a spokesperson for Rolls-Royce told USNI News in a Tuesday statement. “Preparations are underway to swap the engine as quickly as possible to minimize downtime for the ship.”

Due to the unexpected damage to the blades, which have not been found elsewhere in the fleet, Galinis declined to speculate as to what or who was to blame for the issue.

“Until we get the engine out and actually get a chance to do a root-cause analysis, we really don’t know what caused the damage. What I will tell you is we ran the ship at full power and there was no indication of a problem while the ship was underway. We have vibration sensors on the engine to monitor for this type of thing, so even though the damage was there, it wasn’t to the level where we even saw anything on trials. And even, we had additional instrumentation on the engine during trials when we take a ship to sea for testing, and we didn’t see anything,” he said.

Cables running to one of two Advanced Induction Motors on USS Zumwalt. USNI News Photo

For now, because the engines are government-furnished equipment, the Navy will have to pay for the removal of the engine and the installation of the new one. If the problem turns out to be a Rolls-Royce manufacturing or quality assurance issue, the Navy could look to recoup that money from them.

According to NAVSEA spokesman Alan Baribeau, “removal and replacement of the engine is concurrently taking place with the ship’s planned Industrial Post-Delivery Availability at Bath Iron Works shipyard in Bath, Maine. Despite the engine removal, Michael Monsoor is still expected to arrive in her San Diego homeport on schedule by December 2018.”

Michael Monsoor suffered another setback in December 2017, when a problem with the electrical system caused the destroyer to come back to Bath a day after leaving for sea trials. A harmonic filter, which prevents unintended power fluctuations from damaging sensitive equipment in complex electrical systems, failed. The ship was able to resume its sea trials after the electrical system was repaired.

Zumwalt suffered its share of engineering challenges as well, with several propulsion system failures during its transit from Maine to San Diego. The current MT30 problem, though, is unrelated to any other casualty the ship class has suffered to date.

As for the rest of the ship class, Galinis said in his talk that Zumwalt is nearing the end of its combat system activation availability. The destroyer is conducting its lightoff assessment this week and doing well so far, and was preparing to go back to sea by the end of August.

The third and final ship in the class, the future Lyndon B. Johnson (DDG-1002) remains on track at Bath and is set to launch by the end of the year, with sea trials occurring in 2019.

Sam LaGrone contributed to this report.

https://insidedefense.com/insider/monsoor-suffers-engine-damage-prompting-navy-replace-equipment

Monsoor suffers engine damage, prompting Navy to replace equipment

July 11, 2018 |

Justin Katz

The Navy's second Zumwalt-class destroyer Michael Monsoor (DDG-1001) suffered engine damage that has prompted the service to replace that engine before the ship proceeds to San Diego next year, according to an admiral overseeing the ship class.

"Regrettably coming off of her acceptance trial, we found a problem with one of the main turbine engines that drives one of the main generators [and] we're having to change this out," Rear Adm. William Galinis, program executive officer for ships, said during a Navy League event today.

The Navy does not yet know the cause of the damage and won't know until the service conducts a root-cause analysis, he said.

Bath Iron Works is the prime contractor for the Monsoor and Rolls Royce provides the ship's two MT30 Main Turbine Generator Sets.

"The turbine blades -- think of the jet engine on the side of the airplane, the blades that you see -- we actually had some dings, some damage to those turbine blades," Galinis told reporters following the event. "We found that after the sea trial through an [inspection] where you put an optical device inside the turbine to look at" the blades.

Asked whether similar damage occurred on the Zumwalt (DDG-1000), Galinis said the Navy checked and did not find anything.

The service will pay for the removal and repair because the engine is government-furnished equipment, Galinis said.

Following the repairs, the Monsoor is expected in San Diego next year for combat system activation. The Zumwalt is finishing its combat system activation in San Diego right now and is expected back at sea by the end of August, according to Galinis. The Lyndon Johnson (DDG-1002) will start sea trials toward the end of 2019, he said.

Late last year, the Monsoor was forced to return to Bath after experiencing an "equipment failure to a harmonic filter after loss of an induction coil" that prevented the ship from testing propulsion and electrical systems at full power, multiple media outlets reported.

197333

https://sputniknews.com/military/201712121059921539-uss-zumwalt-trials-failure/

US Navy's Top Battleship Zumwalt Reportedly Breaks Down During Trials

© AP Photo / Robert F. Bukaty

Military & Intelligence

11:54 12.12.2017(updated 12:30 12.12.2017) Get short URL

19561

The Zumwalt-class destroyers have faced numerous difficulties in their development and during trials. As costs of the program overran estimates, the Pentagon has reduced the intended number of ships.

Sea trials of the USS Michael Monsoor (DDG-1001), the second Zumwalt-class destroyer made for the US Navy, ended early due to technical problems in the ship’s power system, according to USNI News.

The trials aimed at testing the hull, mechanical and engineering components of the ship kicked off on December 4. According to a statement from the Naval Sea Systems Command (NAVSEA), a harmonic filter failed a day after the ship left the yard and the breakdown forced the destroyer to return to the General Dynamics Bath Iron Works shipyard in Maine on December 5.

Harmonic filters are used in complex electrical systems to prevent unintended power fluctuations from damaging sensitive equipment. The failure of the filter prevented the ship’s power system from running at full power as part of the testing program.

The delay in the trials will not affect USS Michael Monsoor’s delivery, scheduled for March 2018, according to the NAVSEA statement.

A destroyer of the Zumwalt-class is powered by a complex electric system, including two Rolls-Royce MT-30 gas turbines and two Rolls Royce MT-5 auxiliary gas turbines. Its Integrated Power System (IPS) can generate over 75 megawatts of power. According to USNI news, the amount of electricity produced on the Zumwalt-class is "unprecedented in any other non-nuclear surface ship."

The Zumwalt is a class of US Navy guided missile destroyers designed as multi-mission stealth ships. It has a pyramid shaped hull which allows it to dramatically decrease its visibility on radar.

READ MORE: Raytheon Wins $111M for Zumwalt-Class Destroyer Engineering, Testing Services

This is not the first time the cutting-edge Zumwalt-class has experienced technical difficulties. The first ship in the class, the namesake USS Zumwalt (DDG-1000), was floated out last autumn. In November 2016, the ship had to be towed out of the Panama Canal after suffering engine failure.

With a price tag of $4.4 billion per ship, the Zumwalt program has also turned out to be too costly for the US military, with total program costs estimated at nearly $23 billion. Earlier, Defense News reported that the Pentagon had reduced the intended number of Zumwalt destroyers from 32 ships to three.

...

561

by Taboola

Promoted Links

Second Zumwalt Destroyer Needs New Engine After Turbine Blades Damaged in Sea Trials

By: Megan Eckstein

July 11, 2018 10:56 AM • Updated: July 11, 2018 6:05 PM

Destroyer Michael Monsoor (DDG-1001) underway during trials. BIW Photo

This post has been updated to include a statement from Rolls-Royce, and again to include a statement from Naval Sea Systems Command.

Zumwalt-class destroyer Michael Monsoor (DDG-1001) will need to have a main turbine engine replaced before the ship can sail to San Diego for its combat system activation, after suffering damage to the turbine blades during acceptance trials, the Program Executive Officer for Ships told USNI News.

Rear Adm. William Galinis said today that Monsoor remained in Bath, Maine, for a post-delivery availability and that, “regrettably, coming off her acceptance trials we found a problem with one of the main turbine engines that drives one of the main generators; we’re having to change it out. So we’re working very closely with Bath Iron Works, with Rolls-Royce to get that engine changed out before she leaves Bath later this fall and sails to San Diego to start her combat system activation availability next year.”

After his remarks at a Navy League breakfast event, Galinis told USNI News that the MT30 marine gas turbine showed no signs of malfunctioning during the sea trials, but the damage was found in a post-trials inspection.

“The problem we had coming off of acceptance trials was actually the turbine blades – so think of a jet engine on the side of an airplane, the blades that you see – we actually had some dings, some damage to those turbine blades,” he said.

“We found that after the sea trial through what we call a borescope inspection, where we actually put a visual and optical device inside the turbine to kind of look at this. And we determined that it was best to change that turbine out before we actually transited the ship to San Diego.”

Monsoor completed acceptance trials in February, and the Navy accepted partial delivery of the ship in April. According to Naval Sea Systems Command (NAVSEA), the damage was discovered in February during a post-cleaning inspection of the engine.

Galinis said part of the reason it has taken so long to replace the engine is that, with the MT30 being so large, a special rail system is needed to remove the engine and put in a new one. That system hadn’t yet been designed when the Navy realized it needed one, so engineers had to finish the design and then install the system.

“So that’s what’s taken us a little bit,” the rear admiral said.

Galinis said the Navy has already checked USS Zumwalt (DDG-1000) and found no damage to its main turbine engine.

An MT30 in 2010. Rolls-Royce Photo

In the U.S., the $20-million Rolls-Royce MT30 is installed on not only the Zumwalt-class but also on the Navy’s Freedom-variant of Littoral Combat Ships. Internationally, the gas turbine –derived from Rolls’ Trent 800 aviation engine – is in use on the U.K. Royal Navy’s Queen Elizabeth-class carriers, the under-construction Royal Navy Type 26 frigate, the planned Daegu-class frigate for South Korea and the Italian Navy’s new Trieste amphibious warship.

The engine, introduced in 2001, can generate up to 40 megawatts of power and is the key to the Zumwalt-class’s Integrated Power System. The MT30s drive the destroyer’s massive electrical grid that drives everything from the ship’s sensors to a massive electric motor that drives the ship’s shafts.

“We’re working closely with the U.S. Navy and the team at Bath Iron Works to swap one of the two MT30 gas turbines on Michael Monsoor,” a spokesperson for Rolls-Royce told USNI News in a Tuesday statement. “Preparations are underway to swap the engine as quickly as possible to minimize downtime for the ship.”

Due to the unexpected damage to the blades, which have not been found elsewhere in the fleet, Galinis declined to speculate as to what or who was to blame for the issue.

“Until we get the engine out and actually get a chance to do a root-cause analysis, we really don’t know what caused the damage. What I will tell you is we ran the ship at full power and there was no indication of a problem while the ship was underway. We have vibration sensors on the engine to monitor for this type of thing, so even though the damage was there, it wasn’t to the level where we even saw anything on trials. And even, we had additional instrumentation on the engine during trials when we take a ship to sea for testing, and we didn’t see anything,” he said.

Cables running to one of two Advanced Induction Motors on USS Zumwalt. USNI News Photo

For now, because the engines are government-furnished equipment, the Navy will have to pay for the removal of the engine and the installation of the new one. If the problem turns out to be a Rolls-Royce manufacturing or quality assurance issue, the Navy could look to recoup that money from them.

According to NAVSEA spokesman Alan Baribeau, “removal and replacement of the engine is concurrently taking place with the ship’s planned Industrial Post-Delivery Availability at Bath Iron Works shipyard in Bath, Maine. Despite the engine removal, Michael Monsoor is still expected to arrive in her San Diego homeport on schedule by December 2018.”

Michael Monsoor suffered another setback in December 2017, when a problem with the electrical system caused the destroyer to come back to Bath a day after leaving for sea trials. A harmonic filter, which prevents unintended power fluctuations from damaging sensitive equipment in complex electrical systems, failed. The ship was able to resume its sea trials after the electrical system was repaired.

Zumwalt suffered its share of engineering challenges as well, with several propulsion system failures during its transit from Maine to San Diego. The current MT30 problem, though, is unrelated to any other casualty the ship class has suffered to date.

As for the rest of the ship class, Galinis said in his talk that Zumwalt is nearing the end of its combat system activation availability. The destroyer is conducting its lightoff assessment this week and doing well so far, and was preparing to go back to sea by the end of August.

The third and final ship in the class, the future Lyndon B. Johnson (DDG-1002) remains on track at Bath and is set to launch by the end of the year, with sea trials occurring in 2019.

Sam LaGrone contributed to this report.

https://insidedefense.com/insider/monsoor-suffers-engine-damage-prompting-navy-replace-equipment

Monsoor suffers engine damage, prompting Navy to replace equipment

July 11, 2018 |

Justin Katz

The Navy's second Zumwalt-class destroyer Michael Monsoor (DDG-1001) suffered engine damage that has prompted the service to replace that engine before the ship proceeds to San Diego next year, according to an admiral overseeing the ship class.

"Regrettably coming off of her acceptance trial, we found a problem with one of the main turbine engines that drives one of the main generators [and] we're having to change this out," Rear Adm. William Galinis, program executive officer for ships, said during a Navy League event today.

The Navy does not yet know the cause of the damage and won't know until the service conducts a root-cause analysis, he said.

Bath Iron Works is the prime contractor for the Monsoor and Rolls Royce provides the ship's two MT30 Main Turbine Generator Sets.

"The turbine blades -- think of the jet engine on the side of the airplane, the blades that you see -- we actually had some dings, some damage to those turbine blades," Galinis told reporters following the event. "We found that after the sea trial through an [inspection] where you put an optical device inside the turbine to look at" the blades.

Asked whether similar damage occurred on the Zumwalt (DDG-1000), Galinis said the Navy checked and did not find anything.

The service will pay for the removal and repair because the engine is government-furnished equipment, Galinis said.

Following the repairs, the Monsoor is expected in San Diego next year for combat system activation. The Zumwalt is finishing its combat system activation in San Diego right now and is expected back at sea by the end of August, according to Galinis. The Lyndon Johnson (DDG-1002) will start sea trials toward the end of 2019, he said.

Late last year, the Monsoor was forced to return to Bath after experiencing an "equipment failure to a harmonic filter after loss of an induction coil" that prevented the ship from testing propulsion and electrical systems at full power, multiple media outlets reported.

197333

https://sputniknews.com/military/201712121059921539-uss-zumwalt-trials-failure/

US Navy's Top Battleship Zumwalt Reportedly Breaks Down During Trials

© AP Photo / Robert F. Bukaty

Military & Intelligence

11:54 12.12.2017(updated 12:30 12.12.2017) Get short URL

19561

The Zumwalt-class destroyers have faced numerous difficulties in their development and during trials. As costs of the program overran estimates, the Pentagon has reduced the intended number of ships.

Sea trials of the USS Michael Monsoor (DDG-1001), the second Zumwalt-class destroyer made for the US Navy, ended early due to technical problems in the ship’s power system, according to USNI News.

The trials aimed at testing the hull, mechanical and engineering components of the ship kicked off on December 4. According to a statement from the Naval Sea Systems Command (NAVSEA), a harmonic filter failed a day after the ship left the yard and the breakdown forced the destroyer to return to the General Dynamics Bath Iron Works shipyard in Maine on December 5.

Harmonic filters are used in complex electrical systems to prevent unintended power fluctuations from damaging sensitive equipment. The failure of the filter prevented the ship’s power system from running at full power as part of the testing program.

The delay in the trials will not affect USS Michael Monsoor’s delivery, scheduled for March 2018, according to the NAVSEA statement.

A destroyer of the Zumwalt-class is powered by a complex electric system, including two Rolls-Royce MT-30 gas turbines and two Rolls Royce MT-5 auxiliary gas turbines. Its Integrated Power System (IPS) can generate over 75 megawatts of power. According to USNI news, the amount of electricity produced on the Zumwalt-class is "unprecedented in any other non-nuclear surface ship."

The Zumwalt is a class of US Navy guided missile destroyers designed as multi-mission stealth ships. It has a pyramid shaped hull which allows it to dramatically decrease its visibility on radar.

READ MORE: Raytheon Wins $111M for Zumwalt-Class Destroyer Engineering, Testing Services

This is not the first time the cutting-edge Zumwalt-class has experienced technical difficulties. The first ship in the class, the namesake USS Zumwalt (DDG-1000), was floated out last autumn. In November 2016, the ship had to be towed out of the Panama Canal after suffering engine failure.

With a price tag of $4.4 billion per ship, the Zumwalt program has also turned out to be too costly for the US military, with total program costs estimated at nearly $23 billion. Earlier, Defense News reported that the Pentagon had reduced the intended number of Zumwalt destroyers from 32 ships to three.

...

561

by Taboola

Promoted Links