titanium hulls r not new things. it is design to ram enemies vessel

Resources rich USSR was the King of Titanium Hull subs, their subs can dive much deeper than American.

Fucking expensive metal Titanium and mostly produced in Russia.

https://en.wikipedia.org/wiki/Alfa-class_submarine

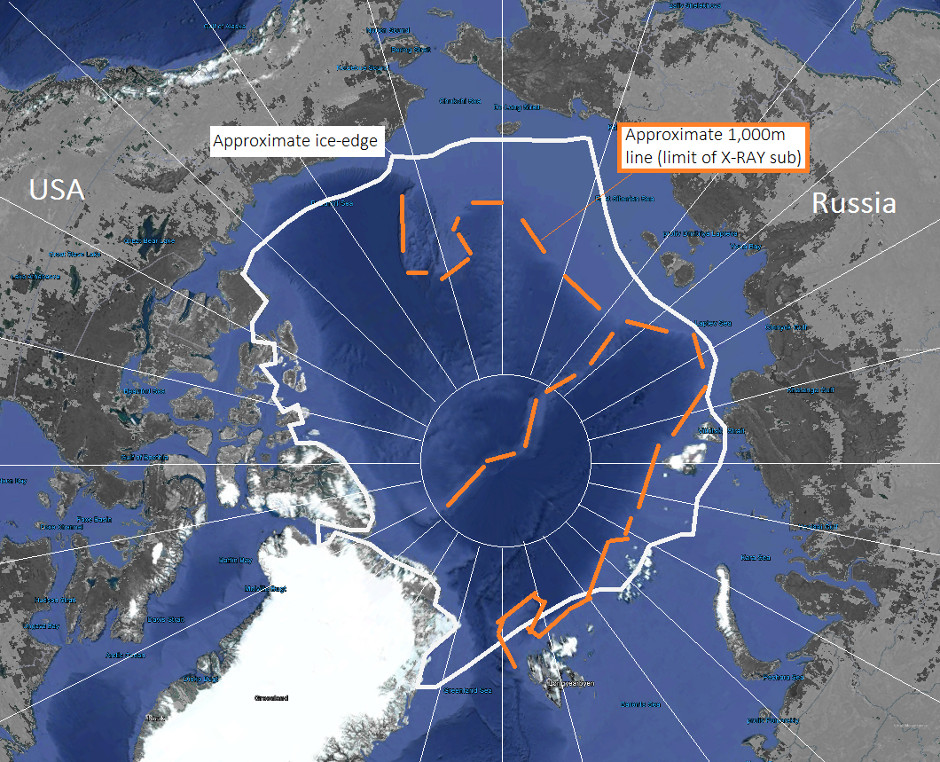

Alfa-class submarine

From Wikipedia, the free encyclopedia

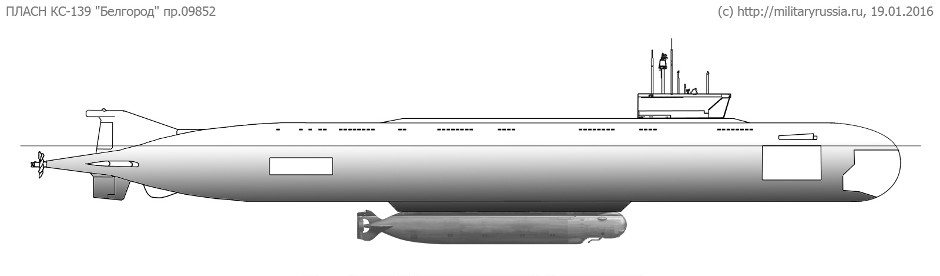

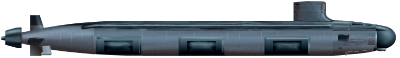

Alfa-class SSN profile

Lira

Lira submarine (Project 705)

Class overview

Name: Lira

Operators:

Preceded by:

Victor class

Succeeded by:

Sierra class,

Akula class

In service: 1977–1996

In commission: 1977–1981

Planned: 8

[1]

Completed: 7

Cancelled: 1

Retired: 7

General characteristics

Type:

Attack submarine

Displacement:

- 2,300 tons surfaced

- 3,200 tons submerged

Length: 81.4 m (267 ft)

Beam: 9.5 m (31 ft)

Draught: 7.6 m (25 ft)

Propulsion:

Speed:

- 12 kn (14 mph; 22 km/h) surfaced

- 41 knots (47 mph; 76 km/h) submerged[1][2]

Test depth: 350 m (1,148 ft) test

[2]

Complement: 31 (all officers)

[1][2]

Armament:

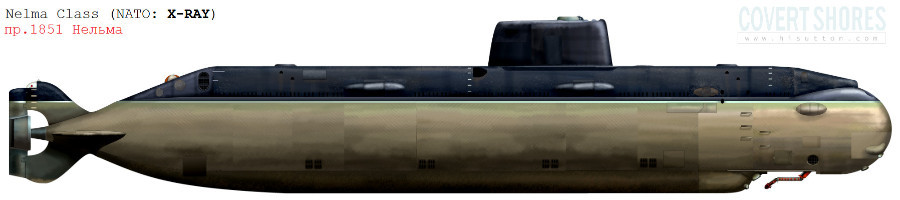

The

Soviet Union/

Russian Navy

Project 705 (Лира/Lira, "Lyre") was a

class of hunter/killer

nuclear-powered submarines. The class is also known by the

NATO reporting name of

Alfa. They were the fastest class of military submarines built, with only the prototype

K-222 (

NATO Papa class) exceeding them in submerged speed.

The Lira was a unique design among submarines. In addition to the revolutionary use of

titanium for its hull, it used a powerful

lead cooled fast reactor as a power source, which greatly reduced the size of the reactor compared to conventional designs, thus reducing the overall size of the submarine, and allowing for very high speeds. However, it also meant that the reactor had a short lifetime and had to be kept warm when it was not being used. As a result, the Liras were used as interceptors, mostly kept in port ready for a high-speed dash into the

North Atlantic.

Contents

Description and history

Preproduction

Project 705 was first proposed in 1957 by M. G. Rusanov and the initial design work led by Rusanov began in May 1960 in

Leningrad[1][2] with design task assigned to SKB-143, one of the two predecessors (the other being OKB-16) of the

Malakhit Design Bureau, which would eventually become one of the three Soviet/Russian submarine design centers, along with

Rubin Design Bureau and

Lazurit Central Design Bureau. The project was highly innovative in order to meet demanding requirements: sufficient speed to successfully pursue any ship; the ability to avoid anti-submarine weapons and to ensure success in underwater combat; low detectability, in particular to airborne

MAD arrays, and also especially to active sonars; minimal displacement; and minimal crew complement. A special

titanium alloy hull would be used to create a small, low drag, 1,500

ton, six compartment

[2] vessel capable of very high speeds (in excess of 40

knots (46

mph; 74

km/h)) and deep diving. The submarine would operate as an

interceptor, staying in harbor or on patrol route and then racing out to reach an approaching fleet. A high-power

liquid-metal-cooled nuclear plant was devised, which was kept liquid in port through external heating. Extensive

automation would also greatly reduce the needed crew numbers to just 16 men. The practical problems with the design quickly became apparent and in 1963 the design team was replaced and a less radical design was proposed, increasing all main dimensions and the vessel weight by 800 tons and almost doubling the crew.

A prototype of a similar design, the

Project 661 or

K-162 (since 1978

K-222) cruise missile submarine (referred to by NATO as the

Papa class), was built at the

SEVMASH shipyard in

Severodvinsk and completed in 1972. The long build time was caused by numerous design flaws and difficulties in manufacture. Extensively tested and reconfigured, she was taken out of service following a reactor accident in 1980. She reportedly had a top speed of 44.7 knots (51.4 mph; 82.8 km/h) and a claimed dive depth of 800 m (2,600 ft). This combined with other reports created some alarm in the

U.S. Navy and prompted the rapid development of the

ADCAP torpedo program and the

Sea Lance missile programs projects (the latter was cancelled when more definitive information about the Soviet project was known). The creation of the high-speed

Spearfish torpedo by the

Royal Navy was also a response to the threat posed by the reported capabilities of the Lira.

Production

Production started in 1964 as

Project 705 with construction at both the

Admiralty yard, Leningrad and at Sevmashpredpriyatiye (SEVMASH — Northern Machine-building Enterprise),

Severodvinsk. The lead unit was a Project 705 design and all subsequent were 705K. The first vessel was commissioned in 1971.

[2] Project 705 boats were intended to be experimental platforms themselves, to test all innovations and rectify their faults, that would afterwards found a new generation of submarines. This highly experimental nature mostly predetermined their future.[

citation needed] In 1981, with the completion of the seventh vessel, production ended. All vessels were assigned to the

Northern Fleet.

General characteristics

- Displacement: 2,300 tons surfaced, 3,200 tons submerged

- Length: 81.4 m

- Beam: 9.5 m

- Draft: 7.6 m

- Depth:

- Usual operation: 350 m

- Test depth: 400 m

- Crush depth: possibly over 1300 m,[3] depth figure contradicted by an authoritative Russian publication.[2]

- Compartments: 6

- Complement: 27 officers, 4–18 NCOs; Russian source: 32[citation needed]

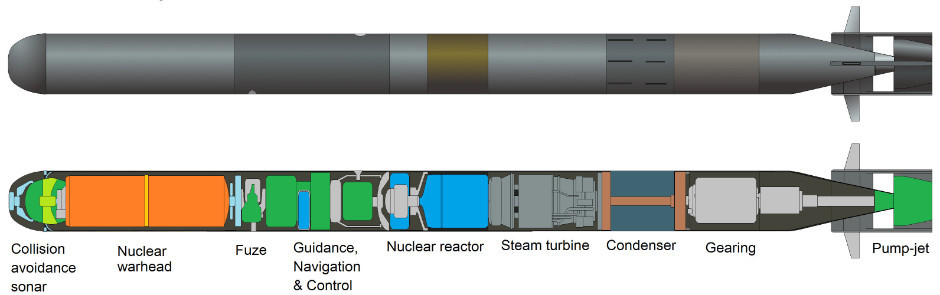

- Reactor: OK-550 reactor or BM-40A reactor, lead-bismuth cooled fast reactor, 155 MW

- Steam turbines: OK-7K, 40,000 shp (30,000 kW)

- Propulsion: 1 propeller

- Speed (submerged): ~40 knots (46 mph; 74 km/h)

- Armament: 6 × 533 mm torpedo tubes:

- Systems:

- Topol MRK.50 (Snoop Tray) surface search radar

- Sozh navigation system radar

- MG-21 Rosa underwater communications

- Molniya satellite communications

- Vint & Tissa radio communications antennas

- Accord combat control system

- Leningrad-705 fire control system

- Ocean active/passive sonar

- MG-24 luch mine detection sonar

- Yenisei sonar intercept receiver

- Bukhta ESM/ECM

- Chrome-KM IFF

Propulsion

The power plant for the boat was a

lead-bismuth cooled fast reactor. Such reactors have a number of advantages over older types:

- Due to higher coolant temperature, their energy efficiency is up to 1.5 times higher.

- Lifetime without refueling can be increased more easily, in part due to higher efficiency.

- Liquid lead-bismuth systems can't cause an explosion and quickly solidify in case of a leak, greatly improving safety.

- LCFRs are much lighter and smaller than water-cooled reactors, which was the primary factor when considering power plant choice for Lira.

Even though 1960s technology was barely sufficient to produce reliable LCFRs, which are even today considered challenging, their advantages were considered compelling. Two power plants were developed independently,

BM-40A by

OKB Gidropress (Hydropress) in Leningrad and

OK-550 by the

OKBM design bureau in Nizhniy Novgorod, both using a

eutectic lead-

bismuth solution for the primary cooling stage, and both producing 155 MW of power.

Designed burst speed in tests was 43–45 kn (49–52 mph; 80–83 km/h) for all vessels, and speeds of 41–42 kn (47–48 mph; 76–78 km/h) could be sustained. Acceleration to top speed took one minute and reversing 180 degrees at full speed took just 40 seconds. This degree of maneuverability exceeds all other submarines and most torpedoes that were in service at the time. Indeed, during training the boats proved able to successfully evade torpedoes launched by other submarines, which required introduction of faster torpedoes such as the American ADCAP or British

Spearfish. However, the price for this was a very high noise level at burst speed.[

citation needed] According to U.S. Naval Intelligence, the

tactical speed was similar to

Sturgeon-class submarines.

[4]

Propulsion was provided by the main

screw with 30 MW steam turbines, and two 100 kW electric-powered screws served as an additional propulsion system for maneuvering, quieter "creeping" (low speed tactical maneuvering), and for emergency propulsion in the event of reactor, turbine, or main screw problems. Backup power systems included a 500 kW

diesel generator and a set of zinc-silver

batteries.

The OK-550 plant was used on Project 705, but later, on 705K, the BM-40A plant was installed due to the low reliability of the OK-550. While more reliable, BM-40A still turned out to be much more demanding in maintenance than older

pressurized water reactors. The issue was that the lead/bismuth eutectic solution solidifies at 125 °C (257 °F). If it ever hardened, it would be impossible to restart the reactor, since the fuel assemblies would be frozen in the solidified coolant. Thus, whenever the reactor is shut down, the liquid coolant must be heated externally with

superheated steam. Near the

piers where the submarines were moored, a special facility was constructed to deliver superheated steam to the vessels' reactors when the reactors were shut down. A smaller ship was also stationed at the pier to deliver steam from her steam plant to the Lira submarines.[

citation needed]

Coastal facilities were treated with much less attention than the submarines and often turned out unable to heat the submarines reactors. Consequently the plants had to be kept running even while the subs were in harbor. The facilities completely broke down early in the 1980s and since then the reactors of all operational Lira submarines were kept constantly running. While the BM-40A reactors are able to work for many years without stopping, they were not specifically designed for such treatment and any serious reactor maintenance became impossible. This led to a number of failures, including coolant leaks and one reactor broken down and frozen while at sea. However, constantly running the reactors proved better than relying on the coastal facilities. Four vessels were decommissioned due to freezing of the coolant.[

citation needed]

Both the OK-550 and the BM-40A designs were single-use reactors and could not be refueled as the coolant would inevitably freeze in the process. This was compensated for by a much longer lifetime on their only load (up to 15 years), after which the reactors would be completely replaced. While such a solution could potentially decrease service times and increase reliability, it is still more expensive, and the idea of single-use reactors was unpopular in the 1970s. Furthermore, Project 705 does not have a modular design that would allow quick replacement of reactors, so such maintenance would take at least as long as refueling a normal submarine.[

citation needed]

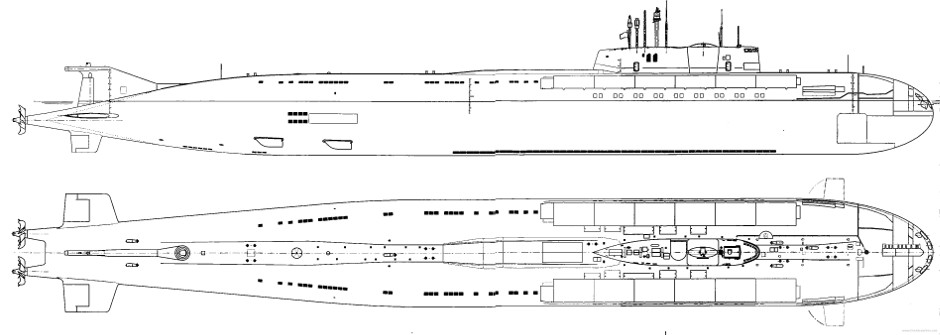

Hull

Like all Soviet nuclear submarines, Project 705 used a double hull, where the internal hull withstands the pressure and the outer one protects it and provides an optimal hydrodynamic shape. However, unlike almost all other submarines, the hulls of the Lira had variable diameters. The shape is optimized for minimal active sonar signature and minimal water resistance and, although it complicated the design, it was essential for providing required maneuverability.

Apart from the prototypes, all six Project 705 and 705K submarines were built with

titanium alloy hulls, which was revolutionary in submarine design at the time due to the cost of titanium and the technologies and equipment needed to work with it.

[5] The difficulties in the engineering became apparent in the first submarine that was quickly decommissioned after cracks developed in the hull. Later, metallurgy and welding technology were improved and no hull problems were experienced on subsequent vessels. American intelligence services became aware of the use of titanium alloys in the construction by retrieving metal shavings that fell from a truck as it left the St. Petersburg ship yard.[

citation needed]

The internal pressure hull was separated into six watertight compartments, of which only the third (center) compartment was manned and others were accessible only for maintenance. The third compartment had reinforced spherical

bulkheads that could withstand the pressure at the test depth and offered additional protection to the crew in case of attack. To further enhance survivability, the ship was equipped with an ejectable rescue capsule.

[6]

The hull was designed for extreme depths, below the

deep sound layer (at 1 km), but complete redesign of the plumbing and other inter-hull systems was delayed. According to some information,

[3] one of the submarines was tested on depths up to 1300 meters, but submerging to such depths and returning caused permanent damage to equipment, which in a few cycles would make the vessel very unreliable. This test may have been conducted just prior to decommissioning.[

citation needed]

Check it out on Amazon

Check it out on Amazon